|

|

|

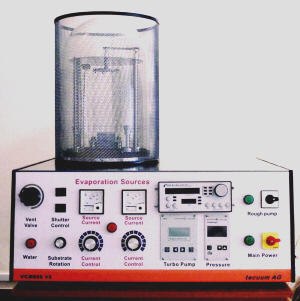

VCM 600 V5

Desktop Vacuum Evaporator

VCM600 V5 is a robust, fast, powerful and simple

to operate desktop Vacuum Thermal Evaporation System.

Industrial grade design and construction with standard, state of the

art, industrial components not software depended, with no parts

obsolescence or PLC bugs, guarantee many years of trouble free

operation.

|

|

The tall glass vacuum chamber

and the excellent geometry of the system,

support the creation

of thin films of metals or other materials on your samples, placed on supplied substrate

holder, with high uniformity, min 95% on dia=10cm substrate, or min 92%

on the optional dia=20cm substrate.

The soft control of heating current intensity allow the fine control of

source's temperature.

FEATURES

• Compact Desktop System

• TWO (2x) High Temperature thermal sources,

1800C, independent driven, co-evaporation

• Cross contamination shields

• Ultra High Grade Aluminum Base plate

• Glass Vacuum chamber (Dia=12" High=19")

• Metallic protection grid.

• High Vacuum Turbo Pump (80l/s) with

TURBO Pump Protection well

• FULL informative TURBO

pump controller

for detailed information and full control on

Turbo pump parameters

•

1000-5.0x10-9 hPa Pirani-Cold Plasma Penning

compact head

vacuum measuring system

• FULL informative controller for compact

Pirani - Cold Plasma Penning head

•

Heating power control unit (PCU) with:

- 2x high current AC power supply

150A continuous, 200A flash evaporation

- 2x Soft, thyristor, 0-100% current control

- 2x analog current meter

•

SQM 160, 2CH, thickness monitoring system,

with ONE quartz crystal head (water cooled)

• Substrate holder, SS, circular form, D=10cm

• Substrate rotation 0-40 rpm

• Substrate holder stereotactic system (SS)

• Adjustable source-Substrate holder distance

•

2x Electromagnetic shutters with

adjustable shutter position

• Safety interlocks (User, Turbo, source, SQM)

• Vent Valve

• Oil

type, rough pump, two stage, 100l/min

• Power Control Unit 110 or 220VAC / 50-60 Hz

•

Base pressure < 5.0x10-6 hPa

|

|

| |

|

The, included in the system, wet type rough pump, is placed on the floor

by the desk of the

evaporator to avoid vibrations. This pump is connected to the appropriate port at the

back side of VCM600 and has

high pumping speed 100l/min for short pump down time and ultimate vacuum of 5.0x10-3 hPa.

This pump is controlled from VCM 600.

The glass bell jar is made from

ultra high quality

borosilicate glass, manufactured under

very strict specifications

APPLICATIONS

•

Metal contact layer on substrates

•

Perovskite Solar Cells thin films

•

Organic LED

•

Metallization on parts

OPTIONS

DRY rough pump , Substrate heating (PID ) up 600oC,

more evaporation sources,

Shutters,

extra power module for co-evaporation, Second LTE source for Organic

materials.

|

|

For all units, a

full set of options is offered (at extra cost). |

|